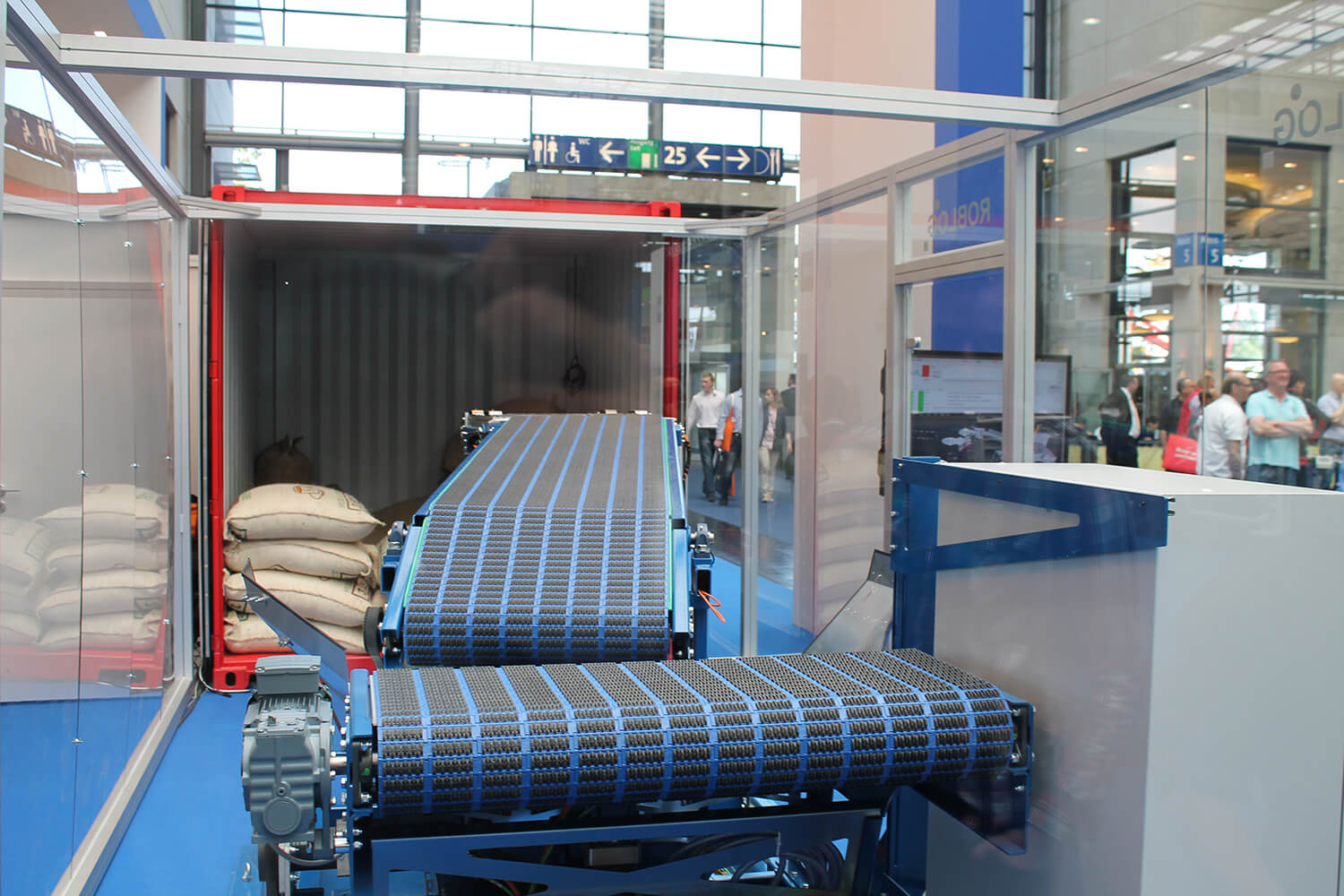

A side view of the Advanced Demonstrator before a testing container filled with heterogenous goods (Image credit: Reutlingen University).

RobLog is currently in progress fine tuning the two demonstrators. Both machines will run the same software for object recognition and motion planning, but differentiate in their applications. The Advanced Demonstrator is a flexible system capable of unloading all kinds of goods found in a container. The advanced-object recognition techniques provide for fast detection and grasping of rigid objects known by the system (e.g. boxes and barrels), while on-line grasp planning techniques can be triggered for the grasping of unknown or flexible objects, using a general purpose compliant gripper. The Industrial Demonstrator was especially designed to autonomous and safely unload heavy-sack shaped goods, using coffee sacks (approximately 75 kg) as the objective goal.

An intermediate version of the Industrial Demonstrator was presented at the CeMAT fair, the world‘s leading trade show for intralogistics[*] , that took place May 19 -23, 2014, in Hannover, Germany.

A rear view of the RobLog Industrial Demonstrator reaching for the next coffee sack to unload (Image credit: Reutlingen University).

The presence of the RobLog Industrial Demonstrator at such an application-orientated fair was a huge success as this created a direct connection with company representatives who were looking for solutions to implement in the USA, Europe, Asia and the Middle East. Onsite RobLog project members spoke with an array of different principals who meet daily with problems of unloading large, heavy deformable goods such as dirt, sand, flour, sugar and rice. Immediate connections were drawn for potential implementation of such a machine into their facilities, as it could create higher efficiencies by increasing daily output.

Video: “Advanced Scenario Milestone 4 M” about RobLog on YouTube

[*] Intralogistics refers to managing material flows along the entire supply chain (supply chain management).

Check the robots in logistics and transport gallery for further images.

Acknowledgements and Contact:Dipl.-Oec. Teresa Rittel, Research Scientist at ESB Business School

Reutlingen University

Alteburgstr. 150

72762 Reutlingen

Germany

Phone: +49 7121 271 3103

Teresa.Rittel@reutlingen-university.de

www.reutlingen-university.de

www.roblog.eu